Chimney refurbishment is a crucial step in ensuring the functionality and safety of chimneys.

A thorough inspection is first carried out to identify defective parts and repair them if necessary.

A new flue gas pipe is then installed inside the existing chimney.

This measure is often carried out on old, damaged or substandard chimneys in order to improve flue gas routing and comply with legal requirements.

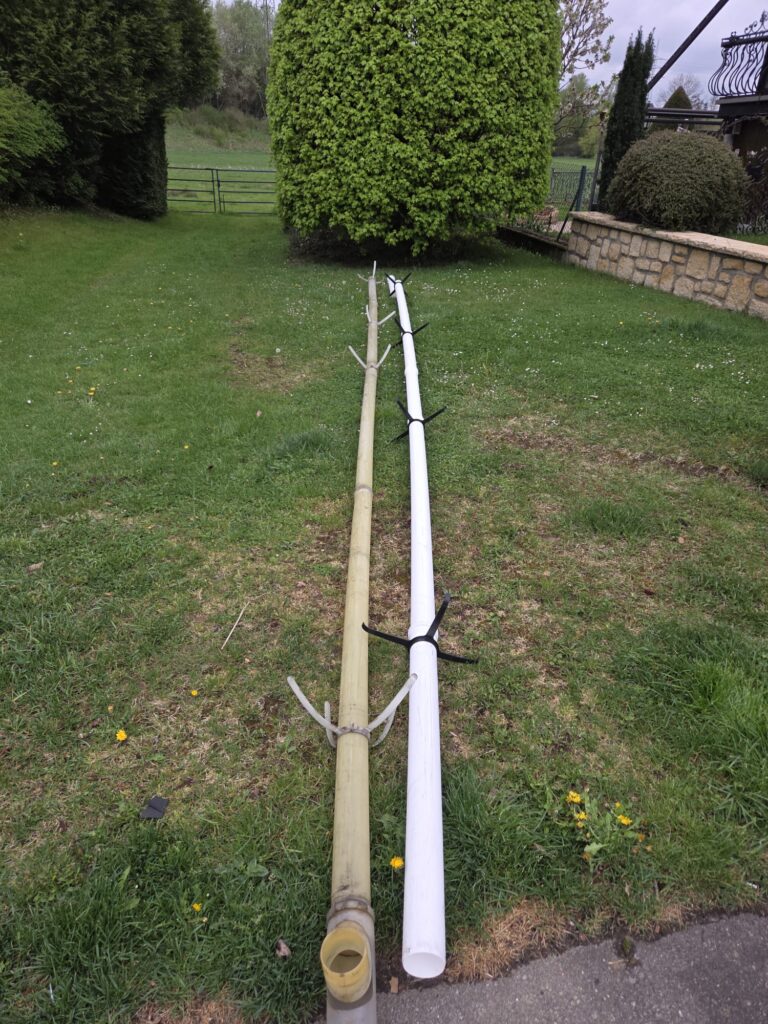

PP renovation:

Refurbishment of the plastic pipework involves replacing or repairing the existing plastic pipe used for flue gas routing.

Over time, plastic pipes can be damaged by exhaust gas and temperature stress, as well as by corrosive substances. During renovation, either a new, robust plastic pipe is used or the existing pipe is checked for cracks and leaks and defective parts are replaced.

The aim is to guarantee safe, standard-compliant flue gas routing and to ensure the longevity of the chimney. This measure is used in particular with modern heating systems.

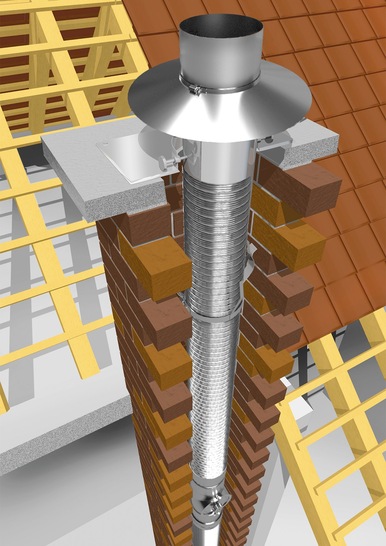

Stainless steel renovation:

Refurbishing the stainless steel pipework of a chimney involves repairing or replacing damaged or outdated stainless steel pipes that are used for flue gas routing.

Stainless steel pipes are particularly resistant to corrosion and high temperatures, but can be affected by many years of use, aggressive exhaust gases or mechanical damage.

Depending on the condition of the flue gas system, either the damaged part is replaced or replaced with a new stainless steel system that ensures safe and efficient flue gas routing.

This measure is often carried out on chimneys with a high volume of flue gas or on older systems in order to maintain the functionality and safety of the chimney and to comply with current safety standards.

Stove pipework:

The stove pipework comprises the internal pipes that connect the stove to the chimney or flue gas system and guide the flue gases safely to the outside.

These pipes are an essential part of any stove, be it a wood-burning stove, pellet stove or gas stove, as they are responsible for proper flue gas routing and the prevention of backdraught or the build-up of pollutants. These parts of the flue gas system usually remain visible, which is why we attach great importance to their visual appearance.

These pipes are often made of stainless steel or refractory material that can withstand high temperatures and corrosion.

It is also possible to insulate the pipework to minimise heat loss and ensure safe handling. Insulated pipes also prevent the exhaust gases from cooling down on the way out, which improves the efficiency of combustion.

References: